Designing and Manufacturing

Machines for Cocoa

We create innovative products technologically advanced and reliable to cover a complete range in terms of productive capacities, which adapts to all your needs.

Machinery

High Production Presses

1

High Production Presses

With our series 900, 980 and the NEW 990 22V, we cover the full range as of productive capacity and we are able to manufacture a “tailor made” line, according to customers’ needs.

All GSR’s presses meet the strict global standards required by the Company Management: quality in the first place and a refined Italian design, capable to ensure high ergonomics and hygiene; essential aspects for a perfect productive cycle. Furthermore the special profiles, ensuring an excellent mechanical resistance in compliance with the requirements for energy saving and safety, feature the equipment with GSR’s standards of efficiency and reliability.

An accurate design of each press allows a remarkable reduction in machine downtime due to cleaning and maintenance.

The NEW 990 series deserves a special attention, a perfect mix between technological innovation and the highest production efficiency compared to the occupied space.

Productive capacities (low fat content cakes):

- series 900 up to 1060 kg/h

- series 980 up to 1540 kg/h

- series 990 up to 1950 kg/h

Machinery

Compact Line

2

Compact Line

Our compact series 870 has been specifically studied for all companies requiring lower capacities than the high production presses ones.

These compact lines consider the use of our presses series 870 which manufacturing philosophy is the same of their “big sisters” of 900, 980 and the NEW 990 series.

Their unique features are:

- Easy and fast installation

- High power and flexibility

- Low managing costs, Total Cost Operation

- High automation standards

- Advanced pressing process control

- High process efficiency

Productive capacities (low fat content cakes)

Series 870 up to 450 kg/h

Machinery

Presses Accessories

3

Presses Accessories

To complete our production presses, we propose some essential accessories for the presses operation:

- Hydraulic group series T3

- Homogenizer series CT

- Product transfer pumps series P4

- Butter scale series BT

- Cake breaker series G

- De-dusting filter

- Press for the filter holding plate mounting type PMT

Machinery

Cooling

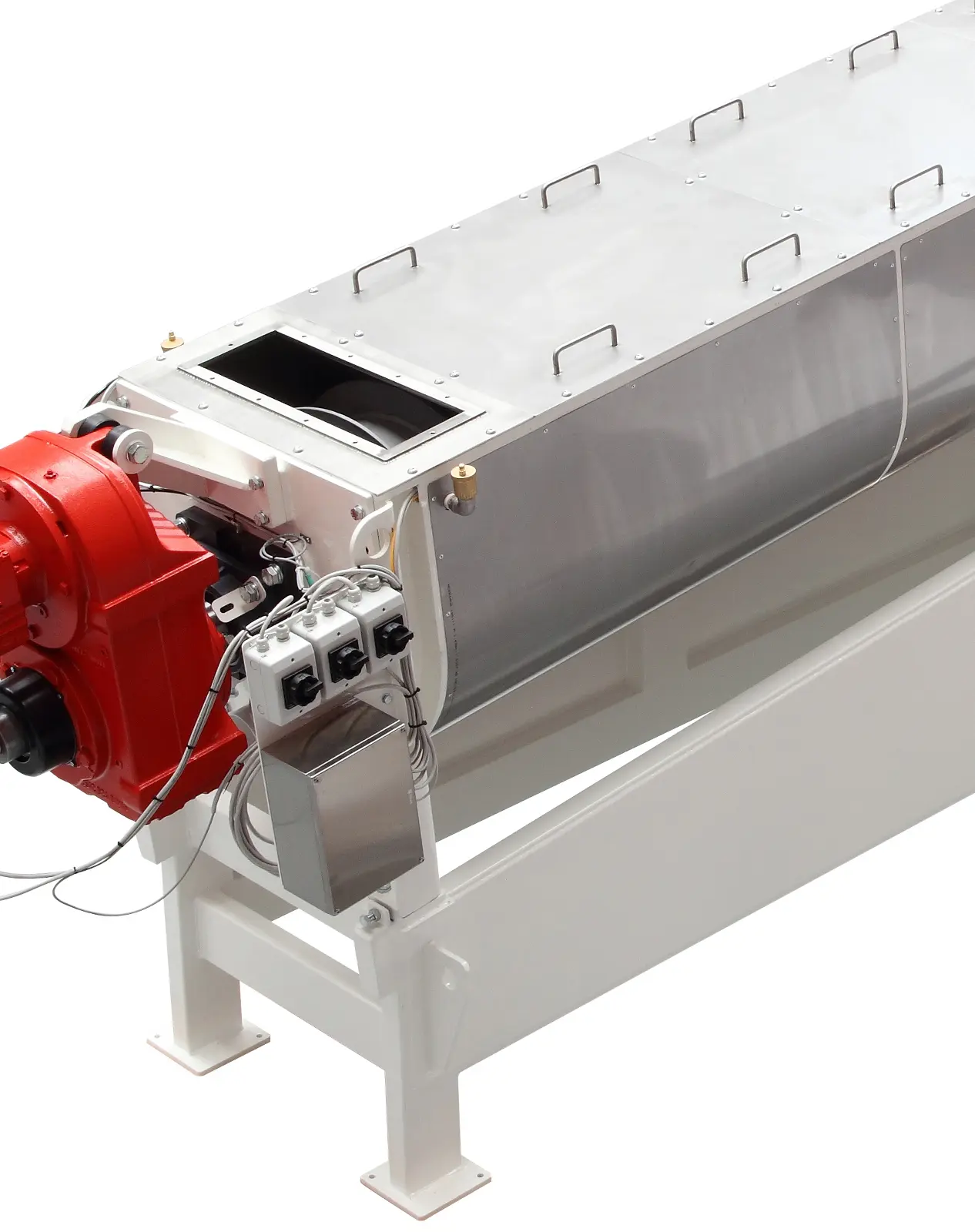

4

Cooling

To avoid any problem by conveying high temperature crushed cakes, there is the possibility to add the pressing line our cooler series CSS, to lower product temperature.

To facilitate this process there is the possibility to equip the cooler with a desiccated air unit blowing dry air into the cooler in order to avoid moisture formation.

Machinery

Filtering

5

Filtering

To improve the quality of the butter got from pressing, eliminating as much as possible the impurities inside, it can be used a filtering system.

According to the productive capacity there are two systems:

- The filter press

- The filter cricket

Laboratory

Presses

6

Presses

We have available the most complete range of laboratory presses with a pressure capacity of 1400 kg/cm2 and 1250 kg/cm2, as well as an automatic line for small productions series 902.

Our laboratory presses are specially designed for research and experimentation of the extraction of fats from any oliy products.

This takes place through a software expressly studied to cross the data of the different tests and getting so the ideal productive cycle.

In spite of their reduced sizes, technology and functionality have nothing to envy to the production presses.

Loading capacity:

- series 1400 from 0,2 to 0,55 litres

- series 1250 4,8 litres

- series 902 up to 50 kg/h

Laboratory

Accessories

7

Accessories

In support of the laboratory presses we propose some accessories to facilitate operators’ work.

- Melting/conditioning system series MT/10

- Cake breaker

Bringing Italian master

to the world.

Efficiency and Reliability

Engineering and perfection

Our strong points

Organization

We have a strong point that enables us to be a well-known warranty in our sector. Reliable delivery times, competitive prices, clear and precise answers and one to one supports are the elements that characterize the way we act...

Read moreState of the art manufacturing: innate quality

We have a strong point that enables us to be a well-known warranty in our sector. Reliable delivery times, competitive prices, clear and precise answers and one to one supports are the elements that characterize the way we act...

Read more